Cover Photo by Andy Wickstrom

Patrick David Sawyer: Founder & CEO of Pisgah Banjo Company

Patrick David Sawyer, originally from Morganton, North Carolina, has been crafting banjos since 2005. He built his first banjo under the guidance of renowned luthier and Appalachian treasure Charlie Glenn of Beech Mountain, NC, while studying at Appalachian State University.

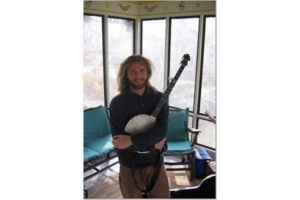

Patrick Holding his first banjo, an AC Fairbanks Reproduction built with Charlie Glynn.

Patrick continued to build banjos using his fathers workshop in Morganton, NC and the Appalachian State University woodworking program, taking many independent studies classes under the skilled guidance of woodworker, mentor and professor Phill Armstrong. Patrick continued working part time as a wood shop assistant to have access to the university shop until he graduated in 2008.

Before launching Pisgah Banjo Company, Patrick earned a bachelor’s degree in Geography/Planning with a minor in Renewable Energy. After graduating, he worked as a student host at the John C. Campbell Folk School in Brasstown, North Carolina, where he pursued blacksmithing, music and woodworking. He went on from there to hike the 2200 mile Appalachian trail in 2009. While hiking in the beautiful hardwood forests of Appalachia, he was inspired with this idea of creating a sustainable banjo company using only Appalachian Hardwoods.

After the Appalachian Trail, he used the little savings he had to purchase a table saw, band saw, and drill press and set up a small shop in a storage unit on Gap Creek Rd. in Fairview NC. He spent the next 5 years making banjos part time and working as a solar technician at FLS Energy in Asheville, NC, gaining valuable skills that would eventually help him build a modern, sustainable banjo factory.

Patrick at the completion of his 2009 NB though hike in 2009. He would go on to do a SB hike with his wife molly in 2019

Somewhere in New England on the AT 2009

Patrick on McAfee Knob in VA. holding a small banjo he hiked with for 1500 miles.

Patrick as a young solar tech working for FLS energy on the roof of a dormitory at Wake Forrest university installing solar thermal panels in 2011

Patrick protesting hate speech by Gary Birdsong aka “the pit preacher” on the campus of Appalachian State University 2007

In 2012, Patrick founded Pisgah Banjo Company in Fairview, North Carolina, with the help of his friend Topher Stephens. Their mission was simple yet profound: to create affordable, professional-quality, handcrafted banjos using 100% native Appalachian hardwoods.

After a few years at Pisgah Banjos, Topher went on to travel the world and lead gap year students on life changing adventures. Topher currently resides outside of Cullowhee NC teaching Nature Education, Mindfulness, and Earth skills though his endeavor Wild Remembering.

Patrick and Topher with their first batch of Pisgah Banjos

Today, Pisgah Banjo Company is one of the premier builders of open-back banjos in the United States. With a dedicated team of nine employees, plus Patrick, the company has produced over 3,500 handcrafted banjos. In its biggest production year, Pisgah built nearly 500 banjos, with plans for steady growth in the coming decade. Every Pisgah banjo is proudly made in the USA using 100% native Appalachian hardwoods in a solar-powered workshop.

Commitment to Sustainability & Innovation

Sustainability is at the core of Pisgah Banjo Company’s business model. The workshop is entirely powered by solar energy, making it the only instrument factory in the world that fully offsets its carbon footprint with renewable energy.

In 2022, Pisgah announced a 3,000-square-foot expansion, bringing the total production space to 7,000 square feet. This addition, featuring a two-story structure and the world’s only banjo factory elevator, enhances efficiency while maintaining the company’s high-quality standards.

Patrick has also embraced Lean manufacturing principles to optimize production. In 2021, Pisgah transitioned from a traditional batch-and-queue system to a one-piece flow process, ensuring the highest quality in a production environment.

Inspiration and Mentors along the way

Patrick made it a mission to visit as many banjo builders and players as possible early on in his banjo journey many of whom have become friends and colleagues. Here are just a few:

Bart Reiter visiting Patrick in Fairview on a motorcycle trip in 2012

Patrick Sawyer and Kevin Enoch in Kevin’s shop in 2015 Patrick Sawyer and Pete Ross in Kevin’s shop in 2015

Patrick Sawyer and Mike Chew outside Mikes shop in 2014 In Minneapolis MN.

Adam Hurt holding a banjo that Patrick built the rim and Dobson tone ring for and Mark Ward made the neck.

Preserving Tradition, Crafting the Future

Patrick’s dedication to craftsmanship, sustainability, and community involvement has solidified Pisgah Banjo Company’s reputation as a leading maker of handcrafted banjos. His work honors and preserves the rich musical heritage of the Appalachian region while pushing the boundaries of modern, sustainable instrument manufacturing. Patrick and his wife Molly along with their two kids Waylon and Rosie live a life of crafting, music, learning, and being outdoors as much a possible in Fairview, NC